Adirondack

Maple Syrup .com is the premier online guide to Maple Syrup & maple

products in the Adirondacks & New York State

A member of the award winning ADIRONDACKS.com

and Lake Champlain Valley.com network of travel sites.

![]()

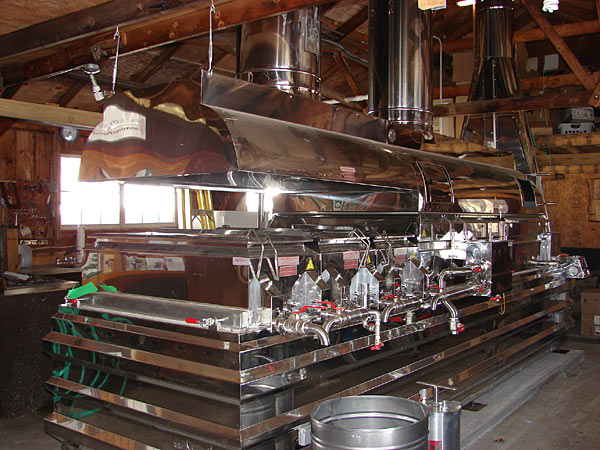

Removing Water from

Sap: Increasing Energy Efficiency with New Technologies

Fresh sap flowing out of the maple tree contains anywhere from 1 6%

sugar. Finished maple syrup is 66-67% sugar. To increase the sugar concentration

of sap, many gallons of water need to be removed. For example, to produce

one gallon of syrup, 43 gallons of sap with 2% sugar content are needed.

This means that 42 gallons of water must be removed from the initial

43 gallons of sap.

In most maple operations, the water is removed by boiling the sap. The cost of fuel needed for boiling is a large part of the total cost of producing maple syrup. Therefore, any increase in fuel efficiency during this process will benefit the maple producer.

Can you think of any ways to increase the efficiency of removing all that water from sap to produce syrup?

There are eight different means of processing sap to syrup. The wood-fired and oil-fired evaporators are basic means of boiling sap. The sap pre-heater increases the efficiency of boiling sap, by recycling steam from the evaporator to warm the fresh sap. The piggyback (steam-enhanced) unit uses both recycled steam and forced air to warm and concentrate the sap before it enters the evaporator. The reverse osmosis, freeze concentration, vacuum evaporator, and vapor compression evaporator use different means to concentrate the sap before it enters the evaporator.

All of these systems have been created by maple producers who enjoyed designing and experimenting with new ways of processing sap. Even today, some of these systems, such as freeze concentration, are still experimental and not commercially available. If you get an opportunity to visit maple producers, you may find some who have designed other systems to recycle steam and increase efficiency. And you may be able to come up with new ways of increasing the efficiency of producing syrup from sap.

We have included

"functional" designs of the different systems to help you

understand the overall process of syrup production. We also hope these

designs will get you thinking about other energy-efficient systems to

produce syrup from sap.

For detailed designs of the different evaporators, contact the manufacturers

or access the U.S. Patent Office web page

information provided by Cornell Sugar Maple Research & Extension Program.

Uihlein Sugar Maple

Research

& Extension Field Station

157 Bear Cub Lane

Lake Placid, NY 12946

Phone: 518-523-9337

The activities conducted at the Uihlein Field Station form the core of the Cornell Sugar Maple Program. The Field Station is located near Lake Placid in the heart of the Adirondack Mountains. It is administered by the Department of Natural Resources, which is part of the New York State College of Agriculture and Life Sciences at Cornell University. The Field Station was established in 1965 with the aid of generous support from Mr. and Mrs. Henry Uihlein II of Lake Placid, New York.

The Uihlein Field Station's 200+ acres of forest provide an outdoor laboratory for the study of forest management and health. Its greenhouse and orchards are at the core of a northeast regional research initiative to identify and cultivate genetically improved maple stock. And its state-of-the-art vacuum tubing and processing equipment enable researchers to develop improved techniques for sap collection and syrup processing. Results of the research projects are shared with maple producers and scientists through papers in professional journals and farmer magazines, trainings, and presentations at the Field Station and throughout New York State, and the Cornell Sugar Maple Website. The Field Station's sugar bush of approximately 4,000 taps, which has shown increasing annual production, is used to demonstrate the merits of new technology and proper forest stewardship to visiting maple producers and landowners.

Description: Many pests and other stresses affect maple trees growing in a sugarbush. Some pests can markedly reduce sap quantity; others, although conspicuous, are not important. Stresses can result from activities by people and from natural phenomena. Recognizing problems and understanding the factors that contribute to their occurrence, development, and significance are necessary to maintain tree health. This report brings together current information on the living agents and nonliving factors that can cause problems in sugarbushes. Insects, diseases, improper forest stand management, and unwise sugaring practices are illustrated, and ways to prevent or reduce their effects are described.

Keywords: insects, diseases, sugar maple, acer saccharum, air pollution, tapping maple syrup, northern hardwoods, maple decline, stand management

43 Broadway

Saranac Lake, NY

Phone: 518-891-3745 Fax: 518-891-3768

E-Mail: RobGrant@northnet.org

This website is owned and operated by

adirondacks.com internet publishing group.

For advertising and editorial content,

please contact Rob Grant;

adirondacks.com reserves the right to reject,

modify or cancel any advertising at its sole discretion.

webmaster: Susan Moore

All copy & images copyright- Adirondacks.com Internet Publishing

Group